ASTM D1894 - Coefficient of Friction Test on Plastic film

Labthink® Coefficient of Friction Tester is designed to determine static and dynamic coefficient of friction tests of plastic films, sheets, rubber, paper, paper board, PP woven bags, fabric style, and metal-material belts for communication cable, conveyor belts, wood, coatings, brake pads, windshield wipers, shoe materials and tyres, etc. Additionally, the instrument could be used to test the smoothness of cosmetics, eye drops and other daily chemical products.

Test Procedures

A: Prepare test specimens according to specific standards.

Based on ISO8295-1986, 2 specimens measuring 200mm×80mm are required for each test. In accordance with ASTM D1894, the size of the test specimen that is to be attached to the plane should be 250mm×130mm and the specimen that is to be attached to the sled should be a 120mm square (if the material of specimen is rigid, it should be a 63.5mm square). If the specimen is greater in thickness or rigidity, please cut a specimen with the same size as that of the lower surface of sled. Generally, the long dimension should be parallel to its machine direction. The specimen surface should be flat and should be free of dust, fingerprints or any foreign matters which may change the surface characteristics.

B: Mount the test specimen.

The connection of load cell and sled should conform to specific standards. In accordance with ISO 8295-1986, load cell is connected to sled via spring and steel wire. If slip occurs, please remove the spring holder and install it back in the opposite direction. Connect the load cell and sled via steel wire directly. In accordance with ASTM D1894, the load cell could be directly connected with the sled via nylon filament.

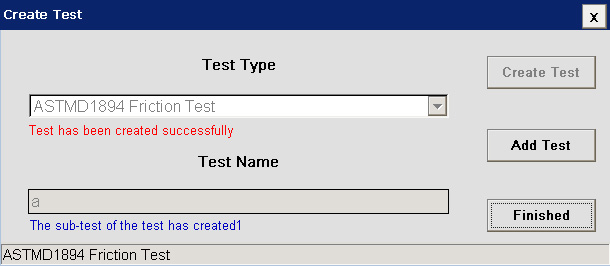

C: Set up test parameters, specimen parameters and then start the test.

D: Record the test data and view the test curve.

If the test curve is not satisfactory, the test should be abandoned and the new test with another specimen should be started.

ASTM D1984 COF Test Video - YouTube

C620H Medidor de COF/Deslaminación

El Medidor de COF/Deslaminación modelo C620H se puede utilizar para medir el coeficiente de fricción estática y dinámica de películas de plástico, láminas, papeles, cartones, bolsas tejidas, telas (prueba de estilo de tela), tiras/correas compuesta de metal y plástico para cables de comunicación y cinturones de transporte, así como prueba de resistencia a deslaminación de productos laminados adhesivos, vendas adhesivas médicas, papeles de liberación y películas de protección.

MXD-02 Medidor de Coeficiente de Fricción

El Medidor de Coeficiente de Fricción MXD-02 está diseñado para pruebas de coeficiente de fricción tanto estática como cinética de películas plásticas, láminas, cauchos, papeles, bolsas tejidas de PP, telas, tiras / correas compuestas de metal y plástico para cables de comunicación, cintas transportadoras, madera, revestimientos, pastillas de freno, limpia parabrisas, materiales para calzados y neumáticos.